Divisions Tecnopresse

Mechanical Design

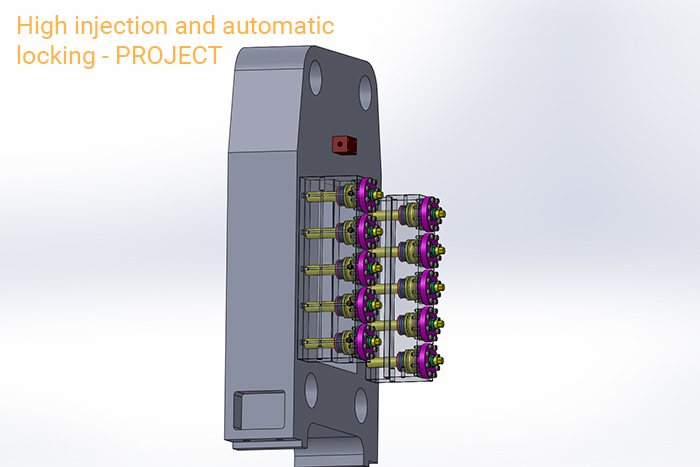

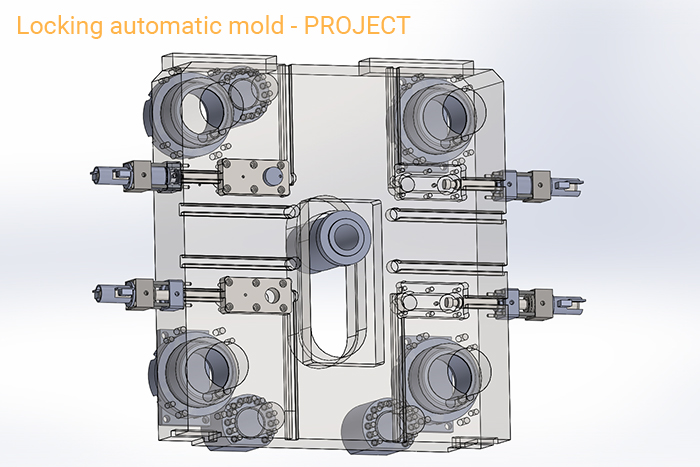

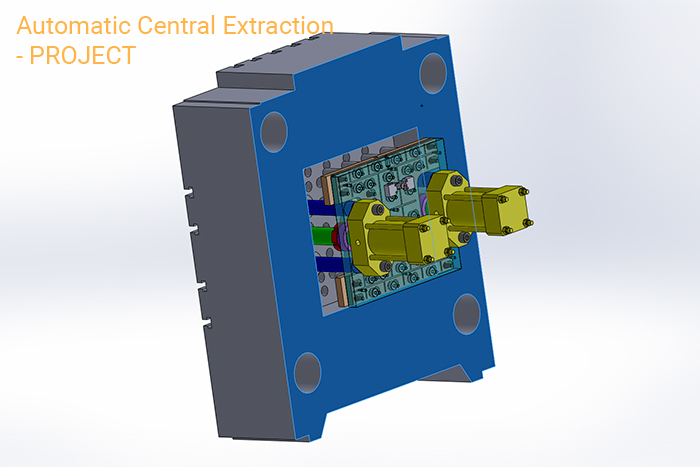

Our design department detects the indications after the disassembling of the details to be able to study the most suitable solution in order to make improvements to the product to make it the most technologically advanced.

Our technicians to develop the projects related to the machines to be produced use the latest generation of equipment and software.

Any upgrades or modifications made to original or new-built items follow the philosophy of using materials available on the market to allow the end customer easy access.

Each modification is designed and documented by means of drawings and statements which are attached to the new instruction book provided upon delivery of the press.

Assembly

Before being dismantled, the press is analyzed in its entirety by the various representatives of all the departments involved, (commercial, workshop, technical office and purchasing office), in order to display and collect all the possible information, thus starting a common procedure and create a synergy between departments, which can lead to the best possible result.

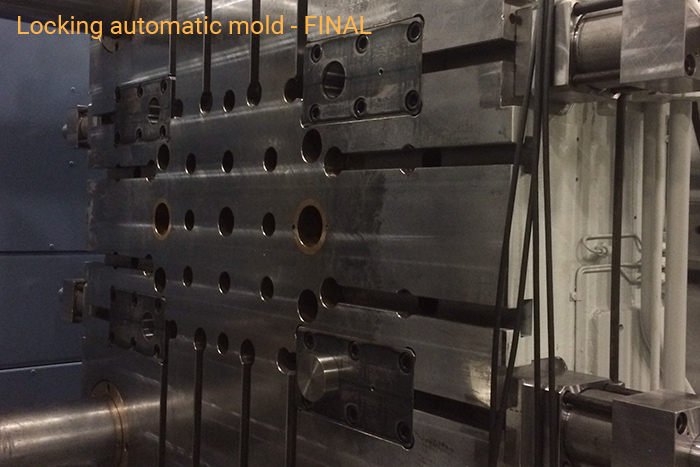

At this point the press is totally disassembled, washed and degreased, making available every single part that will be analyzed from every point of view (visual, dimensional and constructive) by our specialized staff, so that it can identify and direct to the next processing more suitable for functional restoration (chrome plating, grinding, mechanical processing rather than reconstruction).

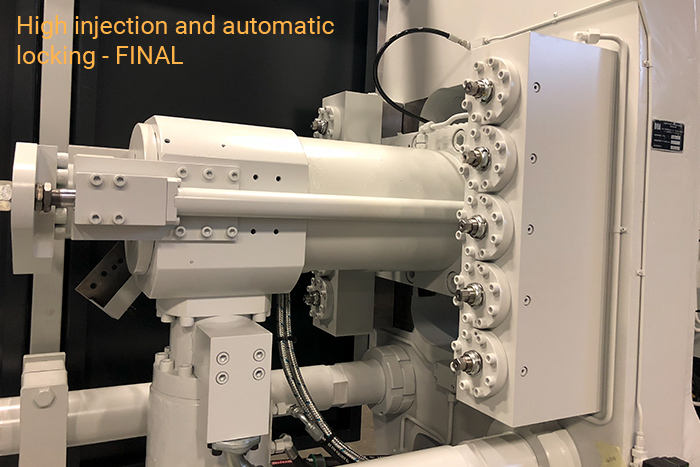

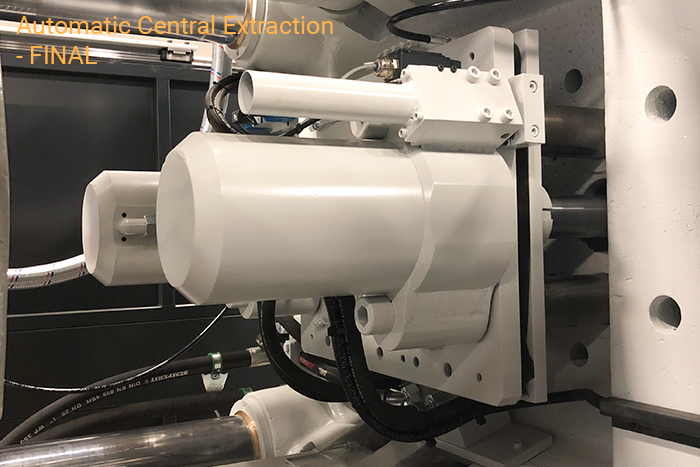

With the return of all the machined or new details, our specialized staff, with the aid of a specific technical data sheet and assemblies of the new parts, proceed with the assembly.

After assembly, the presses are then painted to subsequently receive the electrical system.

Final testing of the plant

When the presses have been completed, they are tested in automatic cycle for 3,000 injections, thus verifying the efficiency of the hydraulic, mechanical and electrical parts, this ensures our customers a guarantee of total reliability for each press produced.

To comply with the European standards, each CE certificate is supplied to each machine.

Assistance

Tecnopresse assistance is born to guarantee customers a complete support, ranging from the supply of spare parts to the support for the maintenance and repair of the plant, it also offers an after-sales service at a distance using the most modern systems of remote tele-service, which allow us to diagnose anomalies, monitor cycle trends and intervene promptly remotely by making any changes or updates to the software.

The department is available to the customer for any training courses on maintenance and management of the machines.

Staff

Beyond machines and technology, it is the staff who make the difference.

The involvement of the whole team in the realization of a product and the passion that each one puts into their work are the best guarantee of reliability and satisfaction for our customers.