Trance Burrs

Main features of the shearing features

Structure:

- done_all Oil tank made of electro-welded sheet metal, where the main cylinder is housed, the hydraulic block.

- done_all The pump and the electric motor are installed externally to the tank to facilitate maintenance.

- done_all The cylinder crosspiece, the moving plane and the fixed plane, are constructed starting from a steel plate with application in various parts of reinforcements by electro-welding, subsequently machined mechanically.

- done_all Shear base built in electro-welded sheet.

- done_all Machine columns in chromed steel.

Hydraulic System:

- done_all Hydraulic system totally designed and supplied by Parker, according to our specifications.

- done_all Cylinder main built to design with internal sliding smoothed.

Central Extraction:

- done_all Plate mounted on a moving surface, made of steel and then mechanically worked.

- done_all Possibility of also exercising prematurezzo function.

Electrical Cabinet:

- done_all Electrical panel made with Siemens components.

- done_all PLC Siemens S7-300.

- done_all Operator panel in three possible solutions.

- done Siemens KP400 in color.

- done Siemens TP700 Touch screen in color.

- done Proface 10” Touch screen in color with free programming of the functions of the shearing.

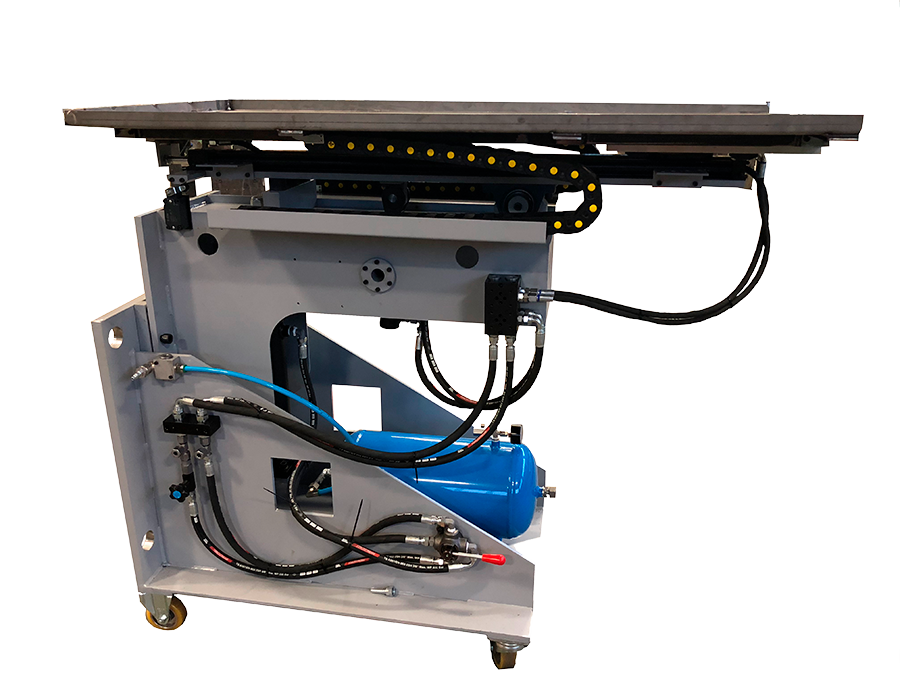

Drainage Slide

Unloading Device:

- done_all Unloading device that can be positioned on all sides by trimming, removable by trolley.

- done_all The device allows automatic removal of pieces according to the shearing cycle.

- done_all All mechanical movements of the unloader take place through guides and ball-bearing trolleys with hydraulic controls, including the height positioning which as an option can also be managed as an accompanying movement for unloading.

- done_all Hydraulic connections facilitated by the presence of quick couplings that allow a quick application.

- done_all Electrical system on board device, with electrical socket in optimal position for easy interfacing with the shearing machine.

- done_all 25Lt air storage tank with connections that allow the blow molding to be cleaned during the inlet and outlet of the machine.