Metal Loader

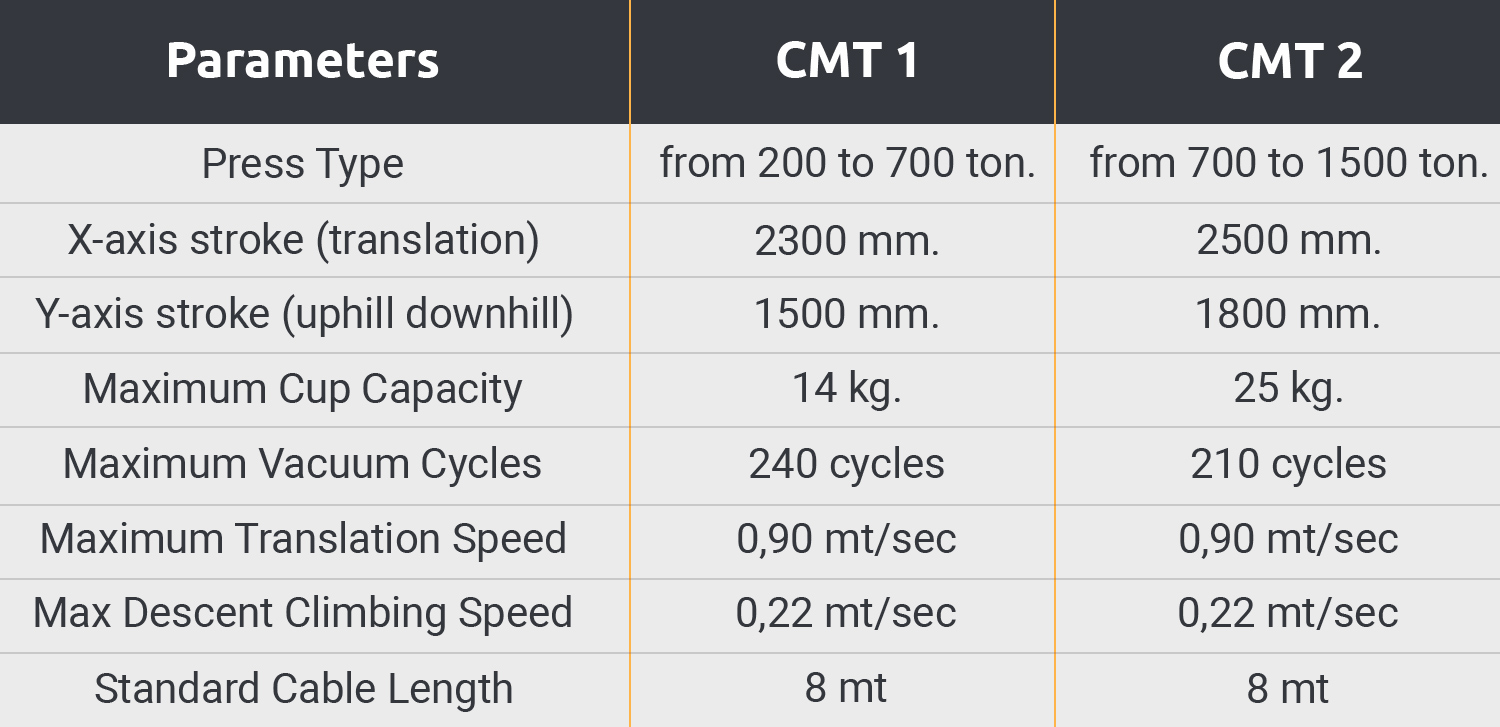

Technical specifications

Translation Axis

Constructed with a supporting beam equipped with hardened guides for the support of the downhill group carriage. Movement by reducer with pinion and rack.

Fixed floor support and adjustable floor lamp, with the possibility to support the loader by positioning the floor lamp in the center of the translation beam (between oven and press).

Travel speed adjustable up to 0.9 mt / sec, through inverter.

Ascent descent axis

Built with a chromed tube driven by two lubricated bushings. The movement is carried out by a reduction gear with pinion and rack.

Fixed ascent and descent speed of 0.22 mt / sec.

Cup rotation axis

Constructed from a chromium-plated rod guided inside the descent-up tube, with forks complete with connecting rods to control the rotation of the cup. The movement is carried out by a reduction gear and a worm screw.

The pouring speed adjustable by inverter.

Software Features

The supplied software guarantees the management of the dosage and of the payment by fast counting, however there is the possibility of dosing in time if necessary. Ability to customize the behavior of the loader in withdrawal phase through numerous times and options. Adjustment of the translation speed and of pouring directly from the operator panel.

Ability to set three changes of speed in the payment phase, you can also manage the payment of the deposit to keep the position of payment constant.

The software has a memory of 120 molds in addition to a high simplicity thanks to an excellent diagnostic support.

Technical Features