Products

Metal Loader

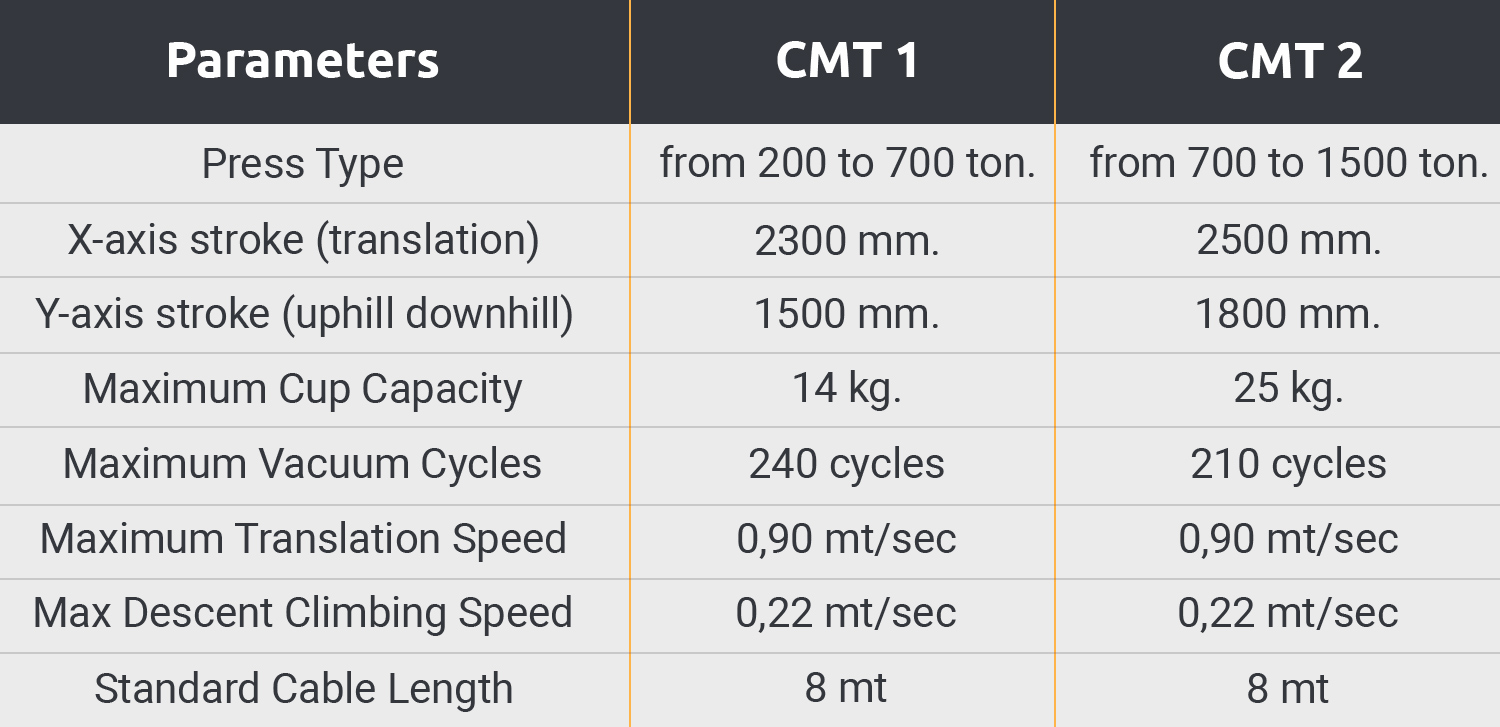

Translation Axis

Constructed with a supporting beam equipped with hardened guides for the support of the downhill group carriage. Movement by reducer with pinion and rack.

Fixed floor support and adjustable floor lamp, with the possibility to support the loader by positioning the floor lamp in the center of the translation beam (between oven and press).

Travel speed adjustable up to 0.9 mt / sec, through inverter.

Ascent descent axis

Built with a chromed tube driven by two lubricated bushings. The movement is carried out by a reduction gear with pinion and rack.

Fixed ascent and descent speed of 0.22 mt / sec.

Cup rotation axis

Constructed from a chromium-plated rod guided inside the descent-up tube, with forks complete with connecting rods to control the rotation of the cup. The movement is carried out by a reduction gear and a worm screw.

The pouring speed adjustable by inverter.

Software Features

The supplied software guarantees the management of the dosage and of the payment by fast counting, however there is the possibility of dosing in time if necessary. Ability to customize the behavior of the loader in withdrawal phase through numerous times and options. Adjustment of the translation speed and of pouring directly from the operator panel.

Ability to set three changes of speed in the payment phase, you can also manage the payment of the deposit to keep the position of payment constant.

The software has a memory of 120 molds in addition to a high simplicity thanks to an excellent diagnostic support.

Technical Features

Lubricators

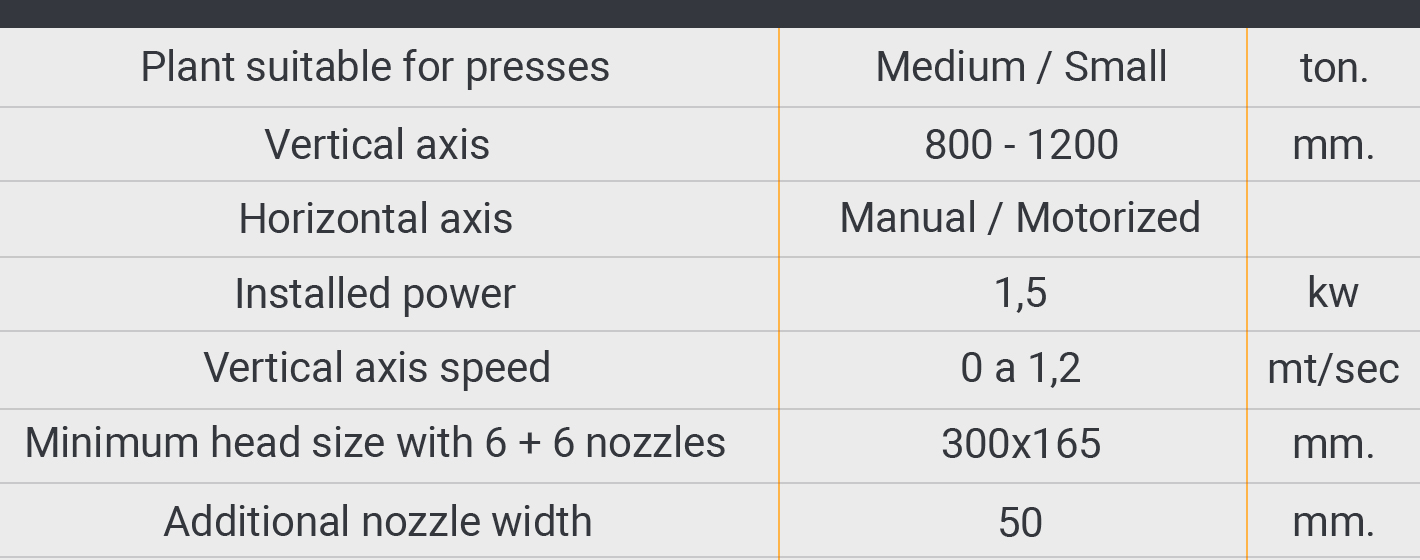

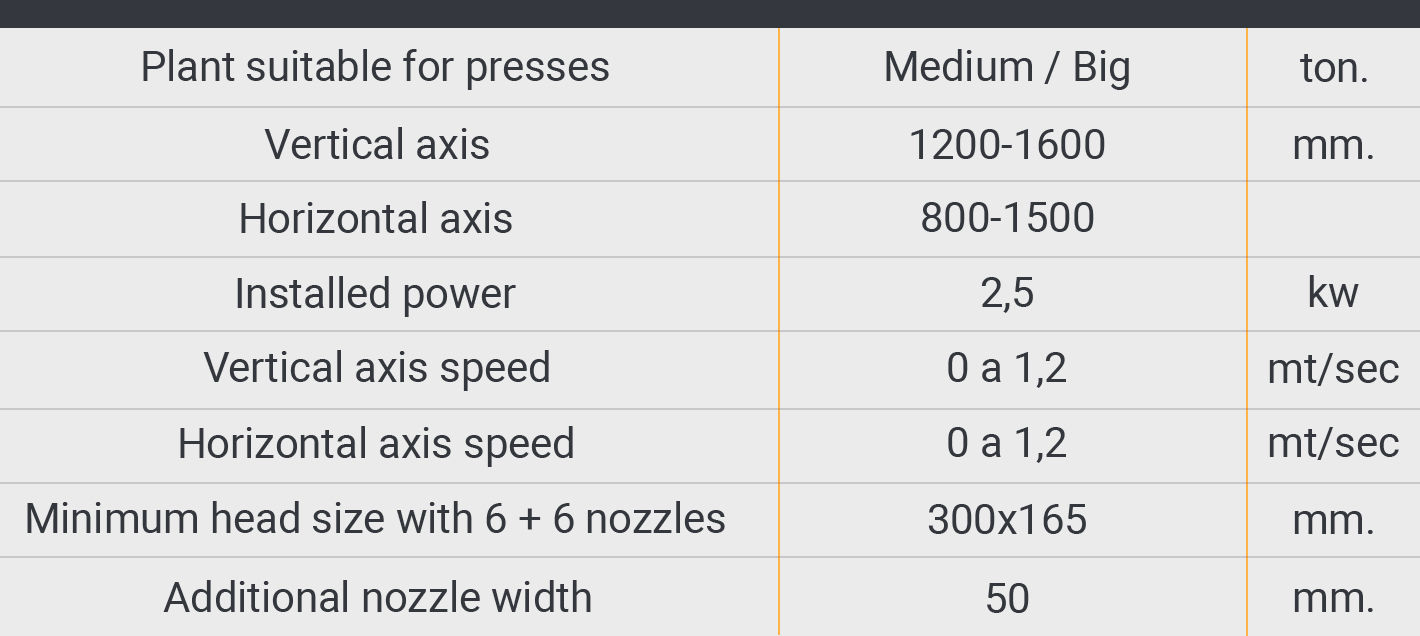

The Tecnopresse range of lubricators is divided into two substantial types

TPL1lubricator suitable for medium-small machines, with the possibility of being mounted on a fixed plane with manual X axis translation or alternatively with positioning motor, rotation table to facilitate the assembly of the molds, lateral translation or on the extraction hood.

TPL2lubricator suitable for medium to large machines with motorized X and Y axis and possibility of interpolation, installation by means of support on a fixed plane.

Both versions have a lubricating circuit, a separate air circuit for blowing and the possibility to manage three separate zones.

We also have the possibility to create an interface in order to adapt any head already in the customer's possession.

The heads supplied by us are modular in order to adapt to every need.

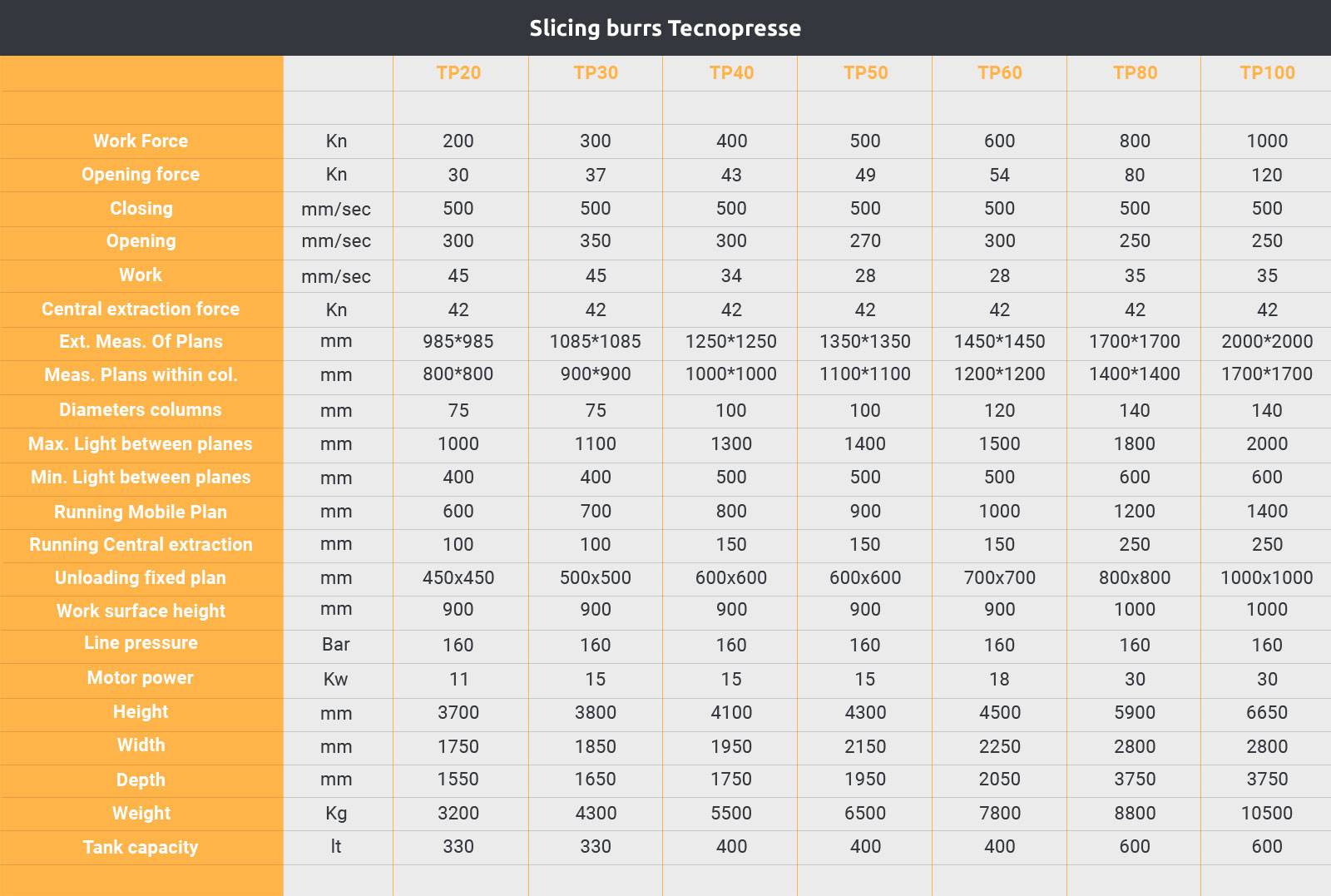

Trance Burrs

Main features of the shearing features

Structure:

- done_all Oil tank made of electro-welded sheet metal, where the main cylinder is housed, the hydraulic block.

- done_all The pump and the electric motor are installed externally to the tank to facilitate maintenance.

- done_all The cylinder crosspiece, the moving plane and the fixed plane, are constructed starting from a steel plate with application in various parts of reinforcements by electro-welding, subsequently machined mechanically.

- done_all Shear base built in electro-welded sheet.

- done_all Machine columns in chromed steel.

Hydraulic System:

- done_all Hydraulic system totally designed and supplied by Parker, according to our specifications.

- done_all Cylinder main built to design with internal sliding smoothed.

Central Extraction:

- done_all Plate mounted on a moving surface, made of steel and then mechanically worked.

- done_all Possibility of also exercising prematurezzo function.

Electrical Cabinet:

- done_all Electrical panel made with Siemens components.

- done_all PLC Siemens S7-300.

- done_all Operator panel in three possible solutions.

- done Siemens KP400 in color.

- done Siemens TP700 Touch screen in color.

- done Proface 10” Touch screen in color with free programming of the functions of the shearing.

Drainage Slide

Unloading Device:

- done_all Unloading device that can be positioned on all sides by trimming, removable by trolley.

- done_all The device allows automatic removal of pieces according to the shearing cycle.

- done_all All mechanical movements of the unloader take place through guides and ball-bearing trolleys with hydraulic controls, including the height positioning which as an option can also be managed as an accompanying movement for unloading.

- done_all Hydraulic connections facilitated by the presence of quick couplings that allow a quick application.

- done_all Electrical system on board device, with electrical socket in optimal position for easy interfacing with the shearing machine.

- done_all 25Lt air storage tank with connections that allow the blow molding to be cleaned during the inlet and outlet of the machine.